Double Flange Triple offset Butterfly Valve

Overview

NSEN Flange type Triple offset butterfly valve could provide both bi-directional sealing and uni-directional sealing, it depends on the customer requirements and working condition. But please notice that different type sealing and sealing structure has the different ranges.

• Multi-layer sealing & Metal to metal sealing

• Bi-directional & Uni-directional

• Low opening torque

• Non-rubbing rotation seating

• Torque seated

• Tilted cone sealing face

Valve Marking: MSS-SP-25

Design & Manufacture: API 609, EN 593

Face to Face Dimension: API 609, ISO 5752, EN 558

End Connection: ASME B16.5, ASME B16.47, EN 1092, JIS B2220, GOST 12820

Test and Inspection: API 598, EN 12266, ISO 5208, ANSI B16.104

Top Flange: ISO 5211

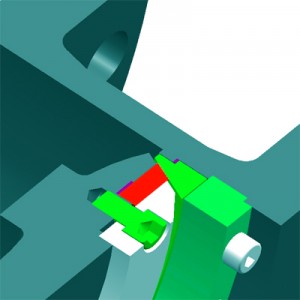

Structure

NSEN provide the option for fixed seat and floating seat which can be repaired without remove the valve from site, it could shorten the maintenance time and greatly improve efficiency. The fixed seat apply to the valve where the medium flow forward , so the tight shutoff sealing is just for one direction, and should pay attention to the flow direction when it was installed . Although the seat are fixed, but the sealing of disc still could be removed. If the valve apply with floating seat, you could install at any direction.

Structure of NSEN floating seat

Low opening torque

This serial uses the Radial Dynamically Balanced Sealing System,by means of optimized design, the forces undertaken on both sides for the butterfly disc inlet and outlet become approximately balanced so as to effectively lower the valve opening torque.

Seal ring material

Seal ring of laminated type is made of stainless steel plate with graphite/ carbon fiber/ PTFE etc. Compare to the rubber asbestos plate material, our adopting material is more wearable, anti-flush, reliable and better for environmental.

Seat ring of metal sealed butterfly valve is made of forged alloy steel which has the advantages of anti-scour, wear-resistance, high pressure and temperature resistance and long life span.

Live loaded packing system

Generally, people only focus on the internal leakage which occurs on the seat part but ignore the external leakage problem, i.e the leakage of packing part. Live loaded packing design with combined structure ensure NSEN Butterfly valve could meet max. leaking ≤20ppm. It makes packing sealing reliable and prolongs the maintenance-free period of packing.

Gear box

The manual gear box offered in high quality and safety structure, which has combined with current well-known brand gear box features and the protection level reach IP 67.

District energy : Thermal power station, heat exchange station, regional boiler plant, hot-water loop, stem pipe system

Refinery : Brine, Carbon dioxide vapor, propylene plant, vapour system, propylene gas, ethylene plant, ethylene cracking device, coking plant

Nuclear power plant : containment isolation, seawater desalination system, brine system, core spray system, pump isolation

Thermal power generation : condenser cooling, pump and steam extraction isolation, heat exchanger, condenser cooling isolation, pump isolation

Low temperature : liquid gas, liquefied natural gas systems, oilfield recovery systems, gasification plants and storage equipment, liquefied natural gas transportation systems

Pulp and paper : steam isolation, boiler water, lime and mud

Oil refining : Oil storage isolation, air supply valve, desulfurization system and waste gas processor, flare gas, acid gas isolation, FCCU

Natural gas

NSEN strictly follow the free repair, free replacement and free return services within 18 months after the valve is ex-works or 12 months after being installed and used on the pipeline after ex-works (upon which comes first).

In the case the valve gets failed due to the quality problem during the use in the pipeline within the quality warranty period, NSEN will provide free quality warranty service. The service shall not be ended until the failure is surely made settled and the valve normally workable as well as the client signs the letter of confirmation.

After expiration of the said period, NSEN guarantees to provide the users with on-time quality technical services whenever the product needs to be repaired and maintained.